What Digital Manufacturing Can Learn From Evolution of Data Telemetry in Formula 1?

Photo: Author

In the world of Formula 1, data telemetry has long been at the forefront of technological innovation, enabling teams to optimize performance and gain a competitive edge. As Formula 1 continues to push the boundaries of digitalization, its advancements often serve as a blueprint for broader industries, including manufacturing. The symbiotic relationship between Formula 1 and manufacturing underscores the transformative power of tele-metrics and other digital solutions in shaping the future of manufacturing.

Last weekend I visited Formula 1 Exhibition in Vienna. Austria hosts F1 Grand-Prix at Red Bull Ring in Spielberg and in 2023 Red Bull Racing Team dominated the series by winning 21 out of 22 Grand-Prix of the season and it made the exhibition long awaited. The exhibition provides a dazzling journey through the world of Formula 1 with variety of interactive displays and immersive design combining modern digital technology with rich content.

Photo: f1exhibition.com

Exhibition was developed in close collaboration with various F1 teams and I must acknowledge, that the level of digitalization and technology at the event really stood up to a Formula 1 standards. Here are few examples:

Online ticket reservation system automatically appointed visitors to the time slot, which helped organizers to optimize the number of people inside the gallery and to assure nice and smooth experience. It worked!

Visitors are handed over an audio set connected to remote control, which allows to point to a receiver installed next to the display. You click to listen to the information (English or German) synchronized with the video. Convenient!

Visitors could also take part in an interactive game of selecting the GOAT (greatest of all time) driver. By selecting different criteria like the era, numbers of podium vs fastest laps, etc. you could immediately see, which driver turns out on which place and submit your vote. Great fun!

Finally there was an impressive multidimensional audiovisual room called The Pit Wall, with large transparent screens, and intensive lights and 3D surround effects. WOW!

Photo: f1exhibition.com

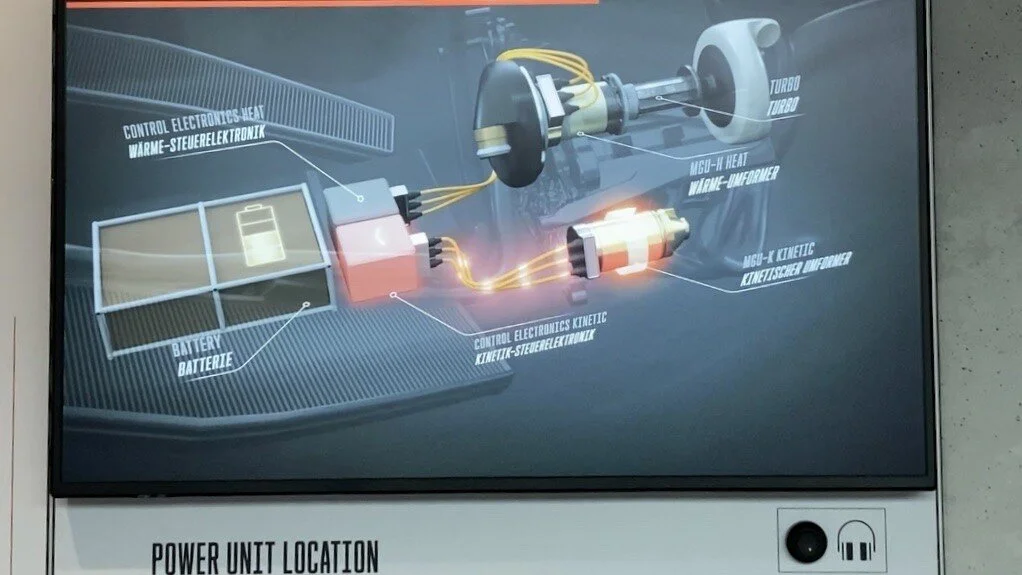

My favorite part of the exhibition was the factory-themed room, where visitors could enjoy a rare glimpse of technologies used in Formula 1. Formula 1 is a laboratory, where new solutions are tested and often adopted in personal vehicles afterwards. Example could be system KERS (kinetic energy recovery system), which has been successfully applied in mild-hybrid power units and commercially offered in series production cars we use today.

Photo: Author

Can you imagine winning races and championships without data telemetry today?

Other exciting technology Formula 1 pioneered and became famous for is data telemetry. The first generations of Formula 1 cars had no sensors and no insights into critical issues. The first telemetry was deployed in 1975 by McLaren in IndyCar series and it was only in the late 1980s (the year I was born) when Williams F1 team introduced it in Formula 1, allowing engineers to monitor various parameters and performance metrics remotely during races and testing sessions.

Photo: Author

But how exactly data telemetry systems works in Formula 1 car these days?

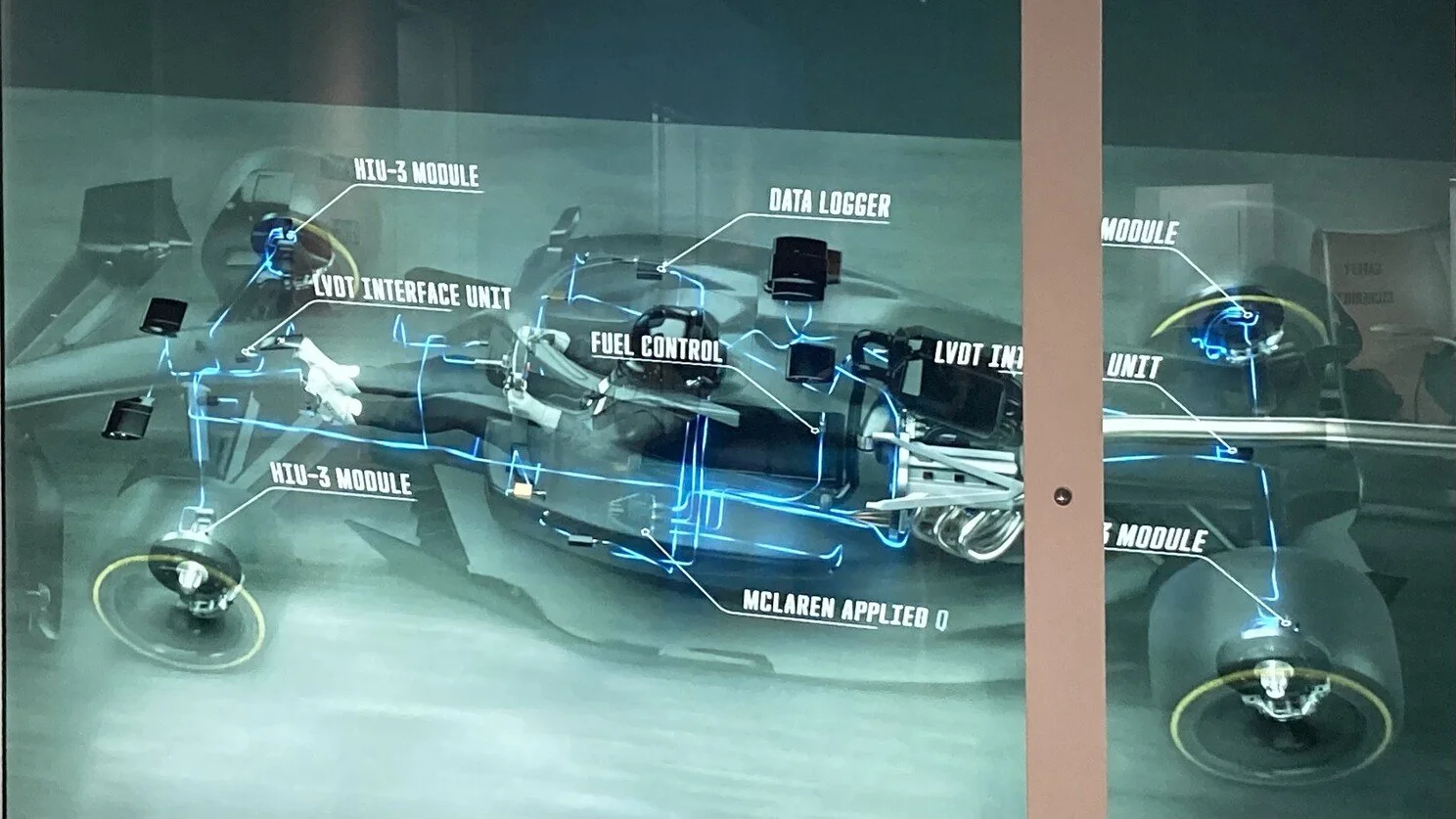

It is a hidden network of cutting-edge electronics consists of 250 sensors and actuators connected by 2km of wires. The ECU (electronic control unit) handles 2000 data channels and acts as a gateway which records, monitors and measures performance indicators of the engine, status of suspensions, gearbox data, fuel status, all temperature and pressure readings, g-force and actuation of controls by the driver in real time. This system is transmitting a staggering 1TB of data (amount equivalent to 1 million e-books) back to the pit wall over a race weekend.

Here are the few examples of sensor types and what they measure in modern Formula 1 car.

Source: F1 McLaren Applied

And how does data telemetry help to win races?

Data is used by engineers during the preparation, qualification and the race itself in three cases:

it provides graphical illustration of what drivers are talking about with their feedback about the behavior of the car

it allows to benchmark and compare two drivers of the same team with each other and understand what works better for individual preferences

if provides a reliability check of parts and components previously unused to predict breaking points, which reduces costs and performance losses

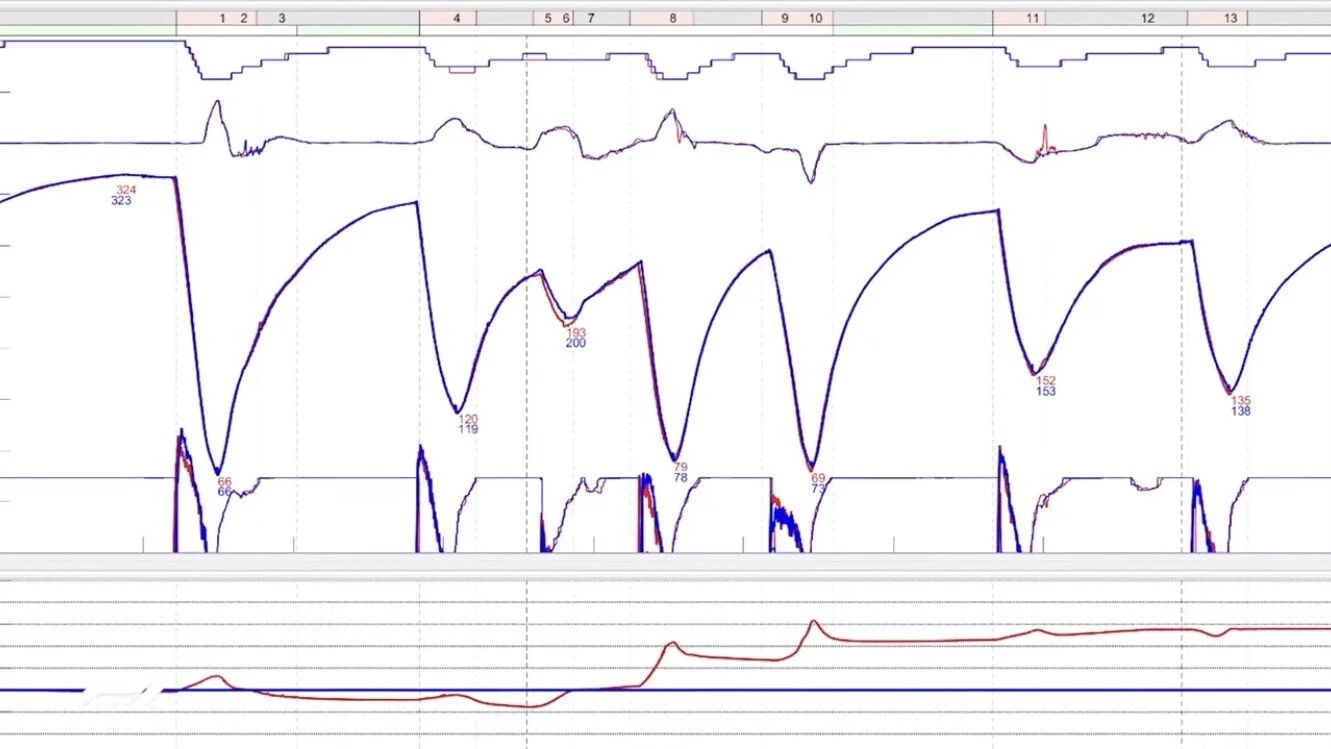

The level of details engineers can read from the data spreads during each corner is helping them to calibrate the car and support drivers in competing within hundred fractions of seconds.

Source: Formula 1

Where is the symmetry between Formula 1 and manufacturing?

Just as Formula 1 teams rely on data telemetry to fine-tune their race strategies and enhance performance, modern manufacturing enterprises are increasingly turning to digitalization to remain competitive in today's market. Just as an old Formula 1 car without telemetry would struggle to keep pace on the track, traditional manufacturing methods fall behind without the integration of digital technologies.

Photo: f1exhibition.com

In ultra-competitive environment, where agility and precision are paramount, embracing telemetry and other digital solutions is not merely advantageous but essential for companies seeking to outpace the competition and thrive in the ever-evolving manufacturing arena.

Application of sensors in manufacturing has never been more accessible and affordable. This is because of IoT (Internet of Things), gateway devices and cloud storage, which allow big data to be managed and understood. But just like in Formula 1, in business digitalization must serve the purpose. Before jumping on the next big technology it is necessary to understand the workflows and interactions to identify the correct critical process issue and critical business issue.

In Formula 1 our critical process issue is the alignment of steering between left and right wheel, which is measured by zero speed and accelerometer sensors and correlated with how the driver attacks each corner. In manufacturing it could be the number of machines settings changes done by an operator and also how well and precise the machine reacts to those changes.

The critical business issue in Formula 1 is the lap time. Therefore the alignment of the steering (critical process issues) is correlated with how fast the car is doing the lap. In manufacturing the number of settings changes and machine regulation (critical process issue) can be correlated with amount of scrap parts and energy consumption per shift, which impact cost and quality (critical business issue).

As Formula 1 enthusiasts waited for years from the initial implementation of telemetry to witnessing real-time data on their television screens during live broadcasts, so too must manufacturing companies recognize that the journey towards full digitalization is one of evolution, not revolution. While the path to widespread adoption may be gradual, the imperative for manufacturers to embark on this journey is clear.

By embracing experimentation with connectivity, data, and information technology, companies can identify and address critical process issues while strategically enhancing overall business performance. Just as Formula 1 teams leverage telemetry to dominate the racetrack, the future of manufacturing lies in harnessing the power of data and digital solutions to secure a winning position in the global market.