What 1946 Arthur Nielsen’s Audimeter Has in Common With 21st Century Industry 4.0?

In this article you will discover:

How Arthur Nielsen's Audimeter collected consumers data in 1946?

What are the symmetries between Audimeter and Industry 4.0?

How Audimeter data were aggregated without the Internet?

How advantages and challenges for data driven solutions hasn't changed that much?

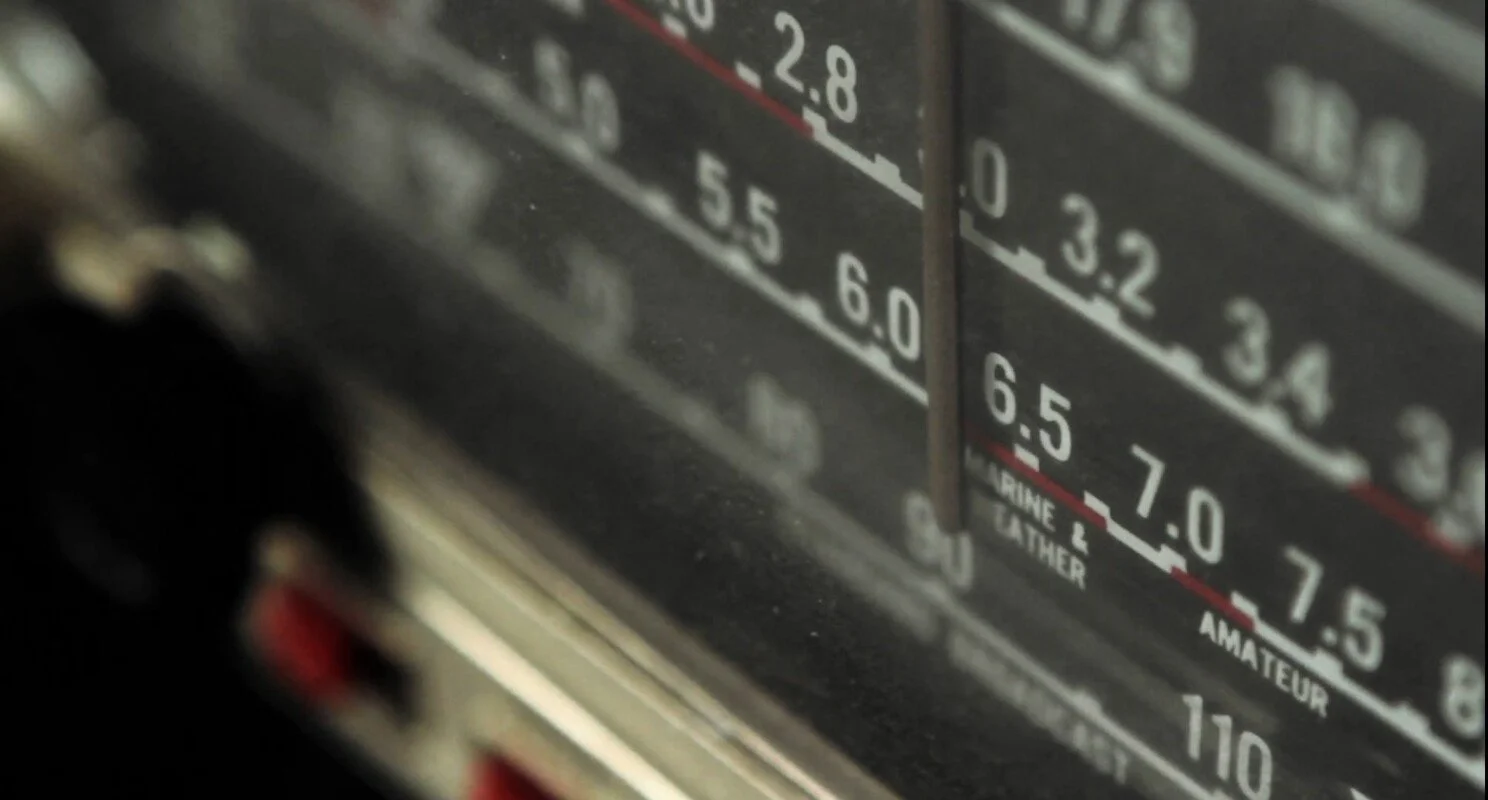

The invention of the Audimeter, a radio tracking device for monitoring radio station listenership was pioneered in 1946 in America by Arthur Nielsen, founder of the market research company Nielsen Holdings.

Source: Curiosity Stream - Connections

Audimeter worked by attaching a small device to a select group of radio sets in households.

Source: Curiosity Stream - Connections

This device would record when the radio was turned on, what station it was tuned to, and how long it was listened to.

Source: Curiosity Stream - Connections

The data collected from these devices provided valuable insights into audience demographics and listening habits, revolutionizing the way radio advertising was measured and marketed.

Source: Curiosity Stream - Connections

The Audimeter data provided by Arthur Nielsen's tracking device revolutionized marketing campaigns by offering advertisers precise information about who was listening to which radio stations and for how long.

By aggregating and analyzing this data, advertisers could make informed decisions about which demographics were most likely to be reached by specific radio stations and tailor their advertising accordingly.

This data-driven approach allowed for more targeted and efficient advertising strategies, ultimately leading to better return on investment for advertisers.

The satisfying symmetry between the Audimeter and Industry 4.0 lies in their utilization of technology to gather data for optimization and efficiency.

1. Data Collection:

Just as the Audimeter collected data on radio listening habits, Industry 4.0 technologies, such as IoT sensors and smart devices, gather data from various points in manufacturing processes.

2. Insights and Analytics:

Both systems use data analytics to derive insights. The Audimeter provided information about radio listenership habits, while Industry 4.0 systems analyze data to optimize production processes, improve quality control, and predict maintenance needs.

3. Optimization:

Both aim to optimize operations based on the insights gained from data analysis. The Audimeter helped advertisers optimize their radio advertising strategies, while Industry 4.0 optimizes manufacturing processes for increased efficiency, reduced downtime, and improved product quality.

4. Technology Integration:

Both the Audimeter and Industry 4.0 involve the integration of technology into existing systems. The Audimeter introduced electronic monitoring to radio broadcasting, while Industry 4.0 integrates digital technologies like AI, robotics, and big data into manufacturing.

In summary, both the Audimeter and Industry 4.0 exemplify how leveraging technology and data can lead to improved insights, optimization, and efficiency in their respective domains.

It must have been challenging to connect radios with Audimeters back in those days and even more challenging to collect and analyze data. How it was done then?

Source: Curiosity Stream - Connections

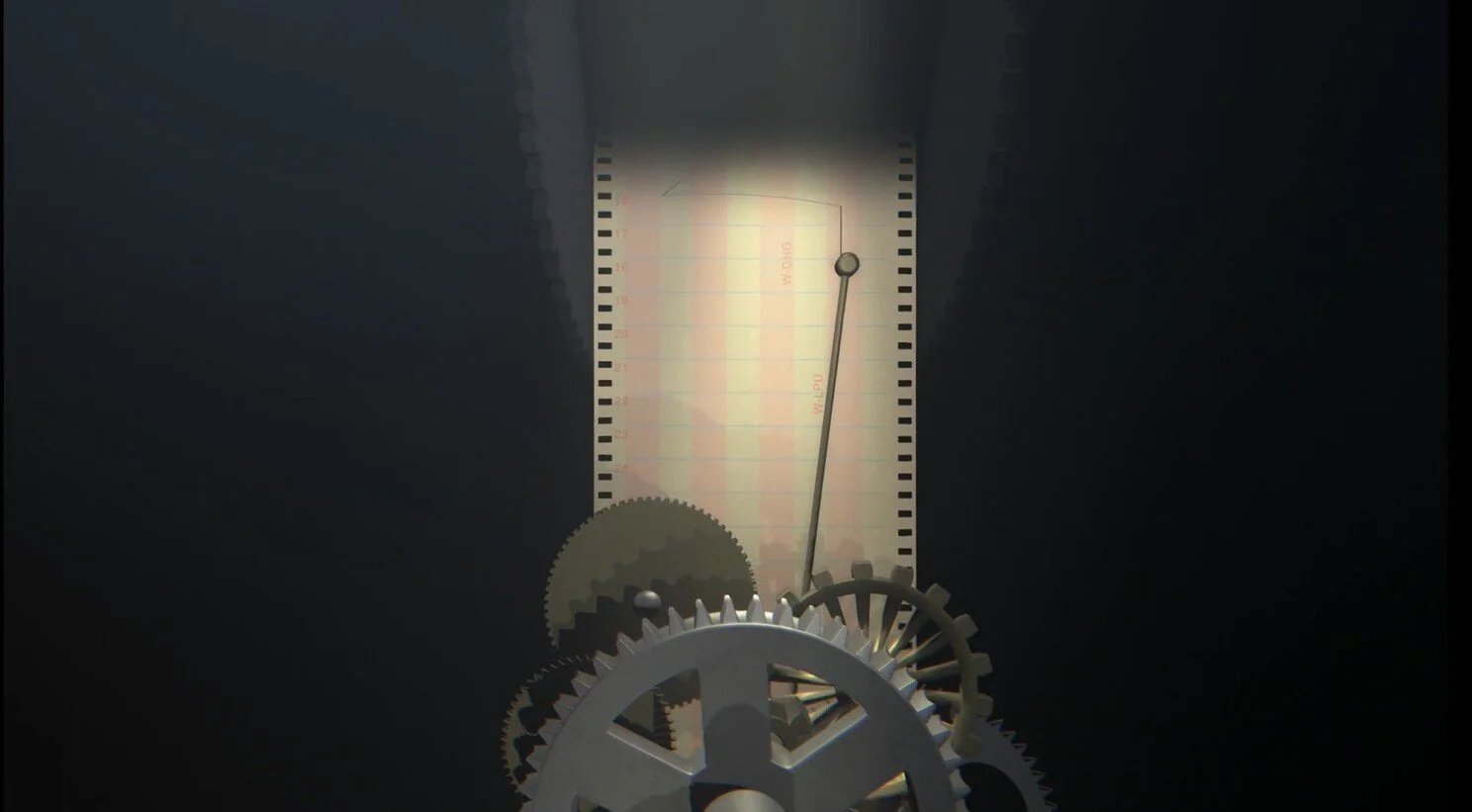

Connecting radios with Audimeters in the early days indeed presented technical challenges. The Audimeter was physically attached to the radio sets in selected households, typically by technicians or representatives from Nielsen. These devices were often small and discreet to minimize interference with normal radio operation.

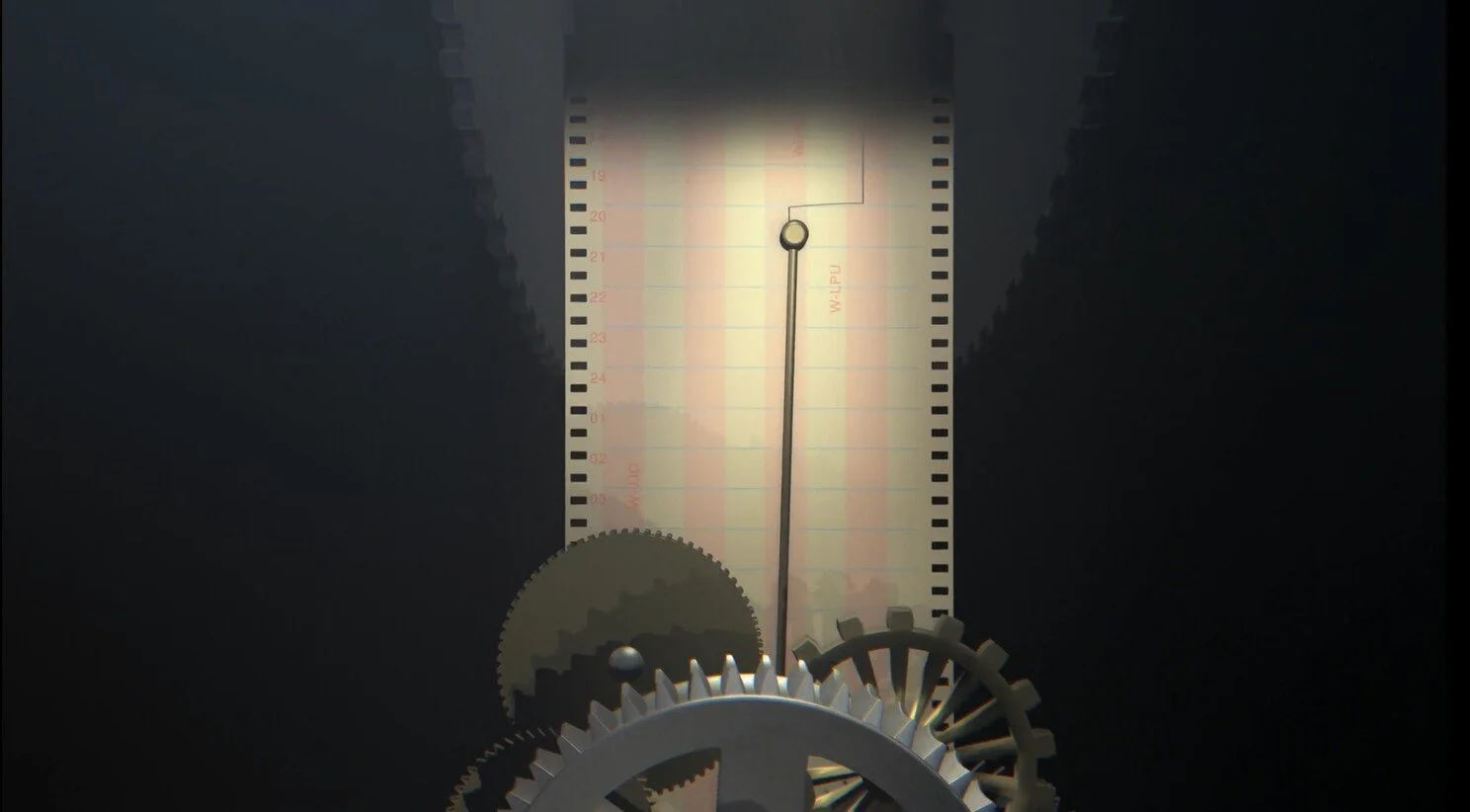

Data collection involved retrieving the Audimeter devices periodically from the households where they were installed. Technicians would collect the devices and then manually extract the data stored within them. This data was typically in the form of analog recordings or simple electronic records.

Once the data was collected, it was manually analyzed by researchers at Nielsen or other market research firms. This analysis involved categorizing and interpreting the data to extract meaningful insights about radio listenership habits, such as which stations were being listened to, when, and for how long.

Overall, while the process was labor-intensive and required significant manual effort compared to modern data collection and analysis methods, it laid the groundwork for the data-driven marketing practices that are common today.

Implementing the Audimeter system in the 40s as well as Industry 4.0 in the 21st century presents both advantages and complexities.

Source: Curiosity Stream - Connections

Advantages:

1. Technology

We now have more advanced technology available for data collection and analysis, such as IoT sensors, cloud computing, and machine learning algorithms. These technologies make it easier to collect, process, and analyze vast amounts of data in real time.

2. Connectivity

Industry 4.0 benefits from widespread connectivity, allowing for seamless communication between machines, systems, and stakeholders. This connectivity enables better coordination, monitoring, and control of manufacturing processes.

3. Automation

Industry 4.0 enables greater levels of automation, reducing the need for manual intervention in data collection and analysis processes. Automated systems can collect, transmit, and analyze data without human intervention, saving time and resources.

Complexities:

1. Integration

Implementing Industry 4.0 technologies often requires integrating new systems with existing infrastructure, which can be complex and costly. Compatibility issues and interoperability challenges may arise when integrating legacy systems with modern technologies.

2. Data Security

With increased connectivity and data sharing comes greater risks to data security and privacy. Protecting sensitive manufacturing data from cyber threats and unauthorized access requires robust cybersecurity measures.

3. Skill Requirements

Industry 4.0 demands a skilled workforce capable of operating and maintaining complex digital systems. Organizations may face challenges in recruiting and training employees with the necessary technical expertise.

Overall, while Industry 4.0 offers many advantages in terms of data collection, analysis, and automation, it also introduces new complexities and challenges that organizations must navigate. However, the potential benefits of increased efficiency, productivity, and innovation make the journey worthwhile for many companies embracing this digital transformation.

If Arthur Nielsen did it in 1946 using basic data collection technologies and manpower for data aggregation and still made positive ROI, manufacturing with 21st century technology can make it happen too.