"Imagine having to run a marathon every day to get food" - What can dolphins teach manufacturing about digitalisation?

Over the last decade my digital efforts were focused on manufacturing in the lightweight polymers domain, but my digital odyssey started much earlier. In 2005 it was the beverage industry, later in 2006, civil engineering but the most interesting chapter in this journey was back in the years between 2009 - 2011, where I was involved in building digital workflows for R&D centers like the Institute of Oceanology Institute of Polish Academy of Science.

Scientists in this institute conducted environmental research and collected biological data during their marine expeditions. They used a sailing vessel to collect data from instruments installed on board and equipped with sensors (IIoT?). Data was aggregated on the local servers (Cloud?) and then converted into valuable knowledge (Artificial Intelligence?) and used during the next research programs or shared within global ocean data networks (Big Data?).

I deliberately put modern technologies in brackets, because even though in 2011 availability of this technology was limited, scientific organisations, who professionally always worked with data, recognized the benefits offered by digitalization way before we declared it a digital revolution in manufacturing. Since manufacturing aims to do exactly the same in business, why not learn from the pioneers who explore nature?

It’s Time to Ask Nature

There are many examples of how manufacturing can learn from nature's design and innovation. Due to my personal experience mentioned above, my favorite examples come from ocean life. For example the researchers found that the whale flippers have unique bumps on the leading edge that reduce drag and increase lift (see picture below). They used this insight to develop a wind turbine blade with a similar shape and texture, which was found to be 32% more efficient than traditional smooth blades.

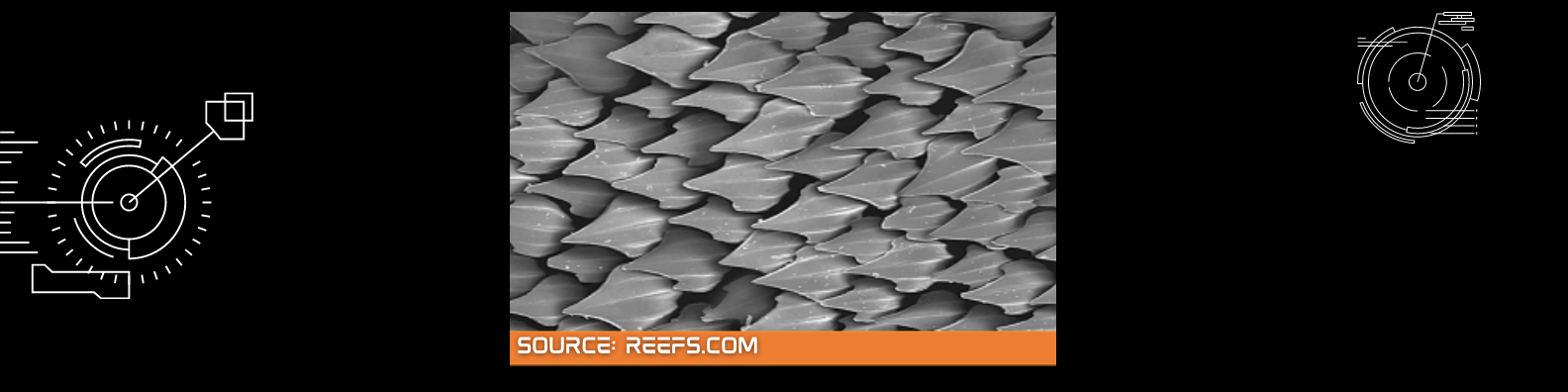

Another example is a low-noise coating developed for wind turbines, which was inspired by shark skin. Some species of sharks can swim at impressive speeds of 50 km/h (31 mph). Their skin is covered in small bony scales called dermal denticles (see picture below) and a solution based on this concept can reduce turbulence and noise while increasing power of wind turbines. Both examples pull inspiration from nature to contribute to the environment and sustainability.

Whales and sharks are fascinating creatures but everyone’s favorite must be the dolphin. I spent a family weekend in Valencia, a Spanish city recognized for its focus on science and sustainability. We visited The City of Arts and Sciences, which is a showcase of the latest advancements in science and technology, and one of its parts - Oceanogràfic Valencia - presented their latest digital innovation used in studying biological processes of dolphins.

Case Study: Digitalization in Biology

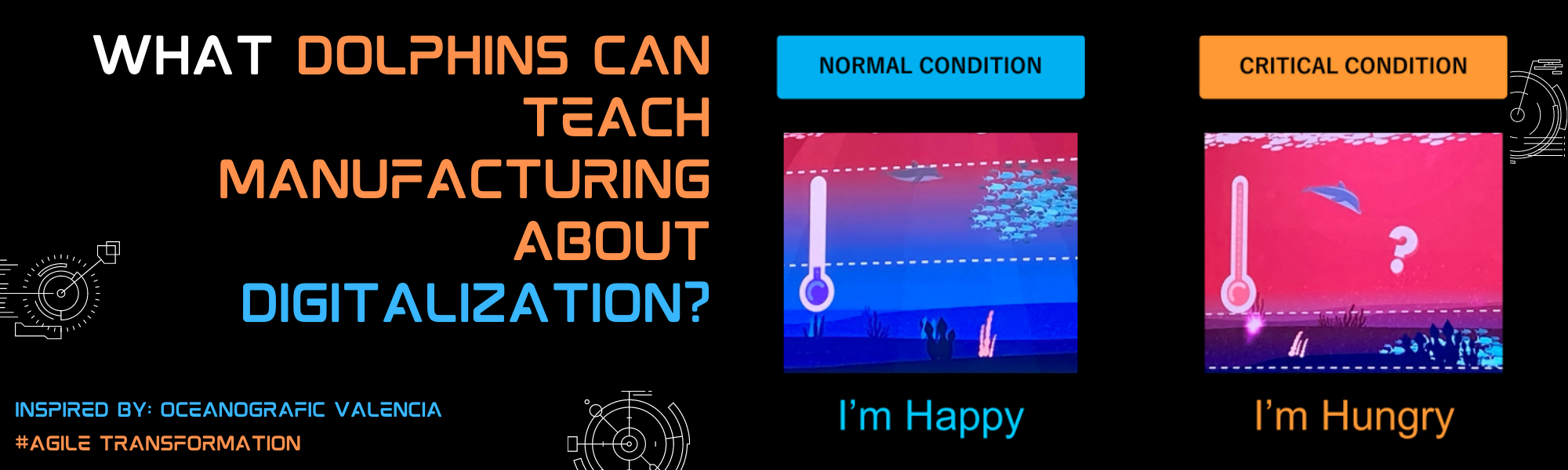

Problem at hand described by Oceanogràfic Valencia

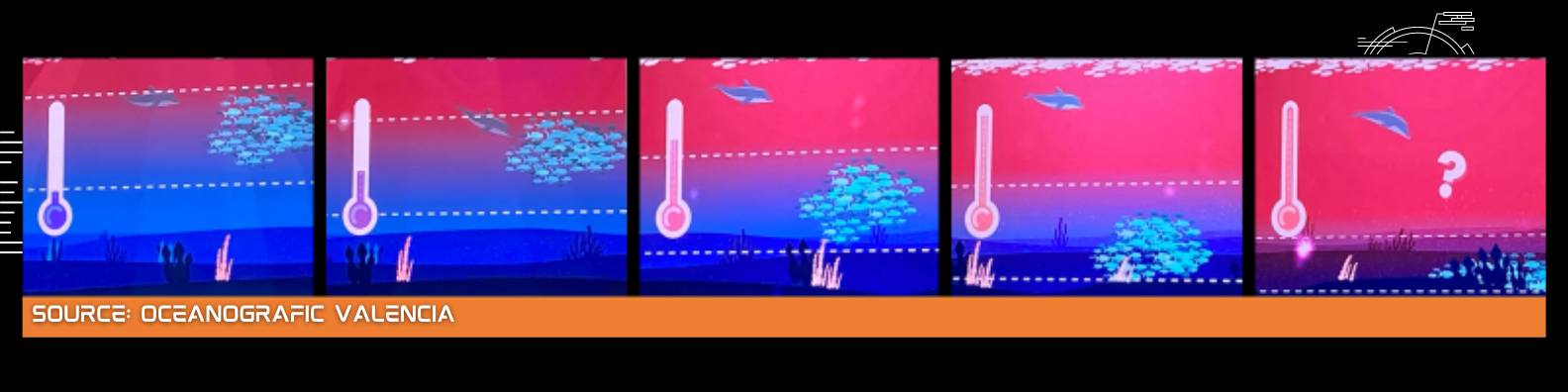

“Climate change is warming marine waters and many fish, seeking cooler waters, travel to greater depths. That’s why dolphins, like many other marine animals, must take greater effort to feed themselves. In extreme conditions dolphins will have to dive really deep and therefore use a lot of energy to find food. Can you imagine having to run a marathon every day to get food?”

These extreme conditions are the subject of research about how it will affect future generations of dolphins and their populations.

Scientists from Oceanogràfic Valencia invented a digital solution, including an instrument for data acquisition called D-Tag and digital spirometer to collect biological data. The D-Tag which monitors the natural environment in which dolphins are living and records parameters like:

Water temperature

Dive depth

Dive duration

Sound recording

Animal activity level

The D-Tag is attached to dolphins back with suction cups. This allows stable attachment without harming the animal. Data is being automatically recorded and transferred to the data center. This part of the solution provides scientists with complete and precise information about the conditions in which dolphins live and changes of those conditions in time function.

When scientists are in direct contacts with dolphins, and they have access to their respiratory organs, they use digital spirometers to collect biological data like:

Lung capacity

Metabolic rate

Disease diagnosis

Gas exchange analysis

Stranding interventions

Complete data sets from D-Tag and digital spirometer can be aggregated and merged together, allowing correlations. Data analysis allows us to search for patterns and identify causations between living conditions and evolution of organs. In the end results, scientists can understand how changes in the natural environment are affecting dolphins' physiological conditions. Scientists can also analyse this information to understand the impact of global warming on dolphins' biological processes and their adaptation behaviors. This knowledge brings them closer to proposing solutions to protect those species.

Applying Nature-Inspired Digital Solutions to Business Problems

Fantastic case study from Oceanogràfic Valencia demonstrates that scientific approach to data, application of analytical methods and modern technologies enables deep understanding of the environment, changes of conditions and their impact on processes. Reversing environmental changes is extremely complex and challenging, but dealing with global warming and devastation of nature is our obligation.

Manufacturing can individually contribute to sustainable development by taking the opportunity to influence their own environment. Measuring manufacturing conditions and acquisition of big data has never been more accessible thanks to IIoT devices. Data security and storage has never been more affordable thanks to cloud solutions. Software providers are equipped with tools and experience to understand specific domains and deliver AI applications centered around business objectives.

Here are the three things small and medium size manufacturing enterprises can try to apply to make a positive impact towards sustainable business development.

Before anything else, try to define the critical business issue you are trying to solve, whether it is reduction of costs or carbon footprint or need for automation. In our case it was an existential threat to intelligent marine mammals. Well defined problem at hand will guide your focus on where to search the right data (which you probably already have) and how to capture it.

Invest time to understand the conditions you are operating at. In our case those were the marine parameters describing the natural environment of a dolphin. You must have noticed that most probably temperature, pressure, frequency and time are probably the same physical parameters, which are critical for your manufacturing conditions.

Search for those features in your conditions data sets, which are impacting the performance of the process or the performance of the results. In our case it was the biological and health condition of a dolphin. In manufacturing it will be energy consumption, carbon emission, cycle times, material waste or quality attributes of products.

Start exploring how you can leverage the power of digital technologies to drive your business forward with agile transformation.

About Valencia

Valencia is recognized for its focus on science and sustainability. The City of Arts and Sciences is a showcase of the latest advancements in science and technology. The city reduces its carbon footprint by promoting cycling and public transportation, segregating waste and reducing energy consumption. University of Valencia has a well-established research program in environmental sciences and has been recognized for its contributions to sustainability.