Redefining Particle Foam Applications With Digital Innovation (@FoamExpo 2024 with JSP Advanced Solutions)

JSP Advanced Solutions @ FoamExpo, Stuttgart 2024 - Presentation by Robert Pluska

Innovation and lightweight have always been cornerstones of the particle foam industry, positioning it as a strong contender against more established technologies like injection moulding. While particle foam stands out for its lightweight properties, structural strength, and acoustic insulation, it often lags in dimensional tolerances and process stability compared to injection moulding. To fully capitalise on its inherent advantages, the industry must embrace evolution and innovation.

The Landscape of Opportunity and Disruption

The particle foam industry is navigating a period of unprecedented change, driven by both challenges and opportunities. Today, vehicles hold between 2-3 kg of particle foam components, a figure projected to grow to 10 kg as manufacturers seek lightweight alternatives to address the weight increase from battery electric vehicle (BEV) architectures. This shift demands precision parts, as traditional injection-moulded components—while heavier—offer superior dimensional tolerances and design flexibility. The challenge lies in closing this precision gap.

In addition to lightweighting, original equipment manufacturers (OEMs) are placing increasing emphasis on sustainable materials and processes. Aligned with the European Union's climate goals, OEMs must achieve a 55% reduction in CO₂ emissions by 2030 (compared to 2021 levels), and a 100% reduction by 2035, effectively transitioning to zero-emission vehicles. These targets drive demand for sustainable materials and processes across the supply chain. Car companies are seeking partners who can deliver solutions that not only meet these objectives but also provide traceability through digital passports and quality management systems.

Emerging supply chain ecosystems like Catena-X are adding another layer of complexity. Catena-X, launched in 2023, is a collaborative data ecosystem designed to standardize data exchange across the automotive value chain. With key industrialisation phases planned into 2025, it emphasises certified interfaces for secure data sharing on quality and carbon footprint metrics. Such capabilities may well become critical factors in future bidding processes.

Amid these challenges, the particle foam industry is also seeing the disruptive potential of technologies like machine learning and artificial intelligence (AI). These innovations are not only transforming the particle foam sector but are set to redefine traditional manufacturing. Forward-thinking leaders have already begun aligning their strategies with this technological evolution, taking tangible actions to secure their competitive advantage.

Actions, not buzzwords! Terms like efficiency, productivity, and sustainability are easy to include in a presentation or a social media post, but real progress demands decisions and the willingness to take risks. The particle foam industry already has the resources to act decisively and minimise risks. This is a game worth playing, and the time to start is now.

Blending Expertise with Technology

The foundation of the particle foam industry is built on its people, who bring decades of experience in design and processing. These experts have shaped the field through their deep understanding of materials, tooling, and production techniques. However, the processes that underpin this ability have still been largely unchanged for over thirty years. While these workflows have been meticulously customized to meet customer demands, they now require modernisation to address emerging challenges and opportunities.

The foundation of the particle foam industry is built on its people, who bring decades of experience in design and processing

Copyrights: JSP

Technology stands for the third critical pillar. Today’s advancements, such as sensors, data analytics, and artificial intelligence, have the potential to revolutionise traditional manufacturing. However, these tools cannot achieve their full potential within outdated workflows. It’s akin to placing a golden roof atop a house in need of structural maintenance—the foundation must be solid for the enhancements to succeed.

Blending human ability with cutting-edge technology is the key to unlocking the next phase of innovation. This integration enables the industry to improve manufacturing techniques, achieve complex geometries with greater precision, and attract a new generation of talent who can drive creativity and set new benchmarks for performance.

The evolution of technology in particle foam manufacturing requires careful attention, particularly as the workforce undergoes a generational shift. Many experienced professionals in the industry possess extensive knowledge about the development of materials, tooling, equipment, and processes. These individuals are steadily exiting the industry, eager to transfer their ability to the next wave of engineers and managers. However, this knowledge transfer is not automatic; it demands a structured approach to succession planning.

To attract and keep the new generation of talent, the industry must align with their expectations. Today’s digital natives, raised on gaming consoles and smartphones, naturally expect advanced, intuitive technology in their professional environments. They are inspired by visionaries like Steve Jobs and Elon Musk, equating technological sophistication with creativity and problem-solving. For them, technology is not just a tool—it is an essential enabler of innovation and efficiency.

This mindset extends beyond the workplace. Young professionals entering the job market at OEMs and end-user organizations expect seamless technological integration throughout the supply chain. They look for suppliers who can provide transparency, traceability, and precision, supported by modern data systems and analytics. Digital passports, connected machines, and advanced analytics are no longer optional; they are prerequisites for building trust and ensuring collaboration.

Furthermore, this generation’s comfort with innovation opens new doors. With the right tools, they can explore uncharted territory in precision and manufacturing excellence, pushing boundaries previously considered unattainable. However, for this potential to be realised, manufacturing plants must adopt robust data systems, integrate sensors, and enable real-time analytics. The industry’s ability to meet these demands will decide its relevance in the eyes of both customers and its future workforce.

Building Trust Through Data-Driven Precision

Trust and precision go hand in hand when it comes to the adoption of particle foam solutions in high-value applications. To compete with established technologies like injection moulding, the industry must deliver consistent quality at a level that inspires confidence in customers. Achieving this requires a transparent, data-driven approach that builds credibility at every stage of the manufacturing process.

Modern manufacturing environments must use real-time analytics to connect production conditions with quality outcomes. Tools like thermal cameras and laser distance sensors ensure precision, projecting full control over production processes. Such instruments not only reassure customers of a supplier's ability to meet stringent specifications but also pave the way for innovation in applications that were previously challenging to industrialise.

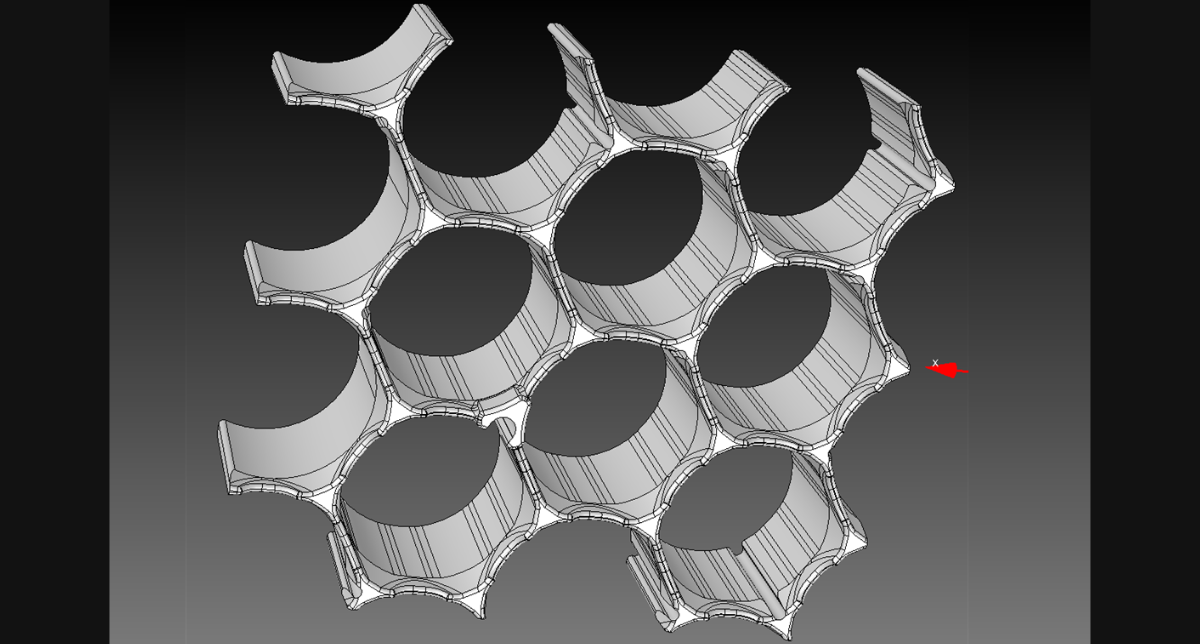

Take the example of the 2017 File Holder Demonstrator—designed and developed by ARPRO team, an engineering milestone featuring walls as thin as 2 mm and a height of 200 mm. In the particle foam industry, such geometries are nearly impossible due to the average bead size of 1.5-2.0 mm, which typically requires three beads for structural stability. This achievement demanded an intricate combination of high-quality materials, finely tuned process parameters, and specialised equipment configurations. While this application highlighted the technical capabilities of particle foam, it initially did not lead to broader market adoption.

Copyrights: JSP

Fast forward to 2024, when the automotive industry—driven by the transition to battery electric vehicles (BEVs)—found a need for lightweight, impact-absorbing materials to protect high-value components like battery packs. The technical requirements for this application mirrored those of the 2017 demonstrator, including strict dimensional tolerances and thin wall geometries. The series production of such parts is virtually unattainable without advanced sensors, data solutions, and a deep understanding of process variables. Thanks to their prior investments in technology and development capabilities, JSP was able to bridge this gap, delivering innovative solutions that exceeded market expectations.

Thin walls made from ARPRO protect batteries in electric vehicles.

Copyrights: JSP

Today, the capabilities developed for these applications are addressing future needs in the automotive sector. With precision parts and hybrid applications (combining particle foam with other materials) set to become standard, manufacturers equipped with advanced analytics and data solutions will have a decisive edge. JSP Advanced Solutions, through its relentless focus on innovation, development, and industrialisation, continues to set benchmarks for the industry, proving that trust and data-driven precision are the cornerstones of success.

Advanced Analytics: A Roadmap for Manufacturers

Copyrights: JSP

Advanced analytics forms the backbone of modern manufacturing innovation, offering unprecedented insights and operational efficiency. However, adopting these solutions requires manufacturers to rethink their infrastructure, data management, and decision-making processes. At JSP Advanced Solutions, we believe in a step-by-step approach that builds confidence and delivers measurable results.

The journey begins with visibility. Simple data illustration tools like dashboards allow production teams to describe the current state of operations and answer the critical question: What happened? By organising raw data from sensors, PLCs, and machines into structured formats, manufacturers can set up a "single source of truth" for shop floor operations. This cuts the reliance on scattered spreadsheets and provides a foundation for deeper analytics.

As data sets become contextualised and organised, the next stage involves diagnosing the root causes of process variations. Analytics tools link process parameters to quality outcomes, answering the question: Why did it happen? This phase enables teams to address inefficiencies and improve production conditions systematically.

Predictive analytics is the next leap forward. By using machine learning models, manufacturers can expect issues before they arise, addressing the critical question: What will happen? In environments with hundreds of influencing factors, machine learning excels at analysing these variables both individually and in combination, finding patterns that are invisible to human operators. This capability reduces waste, improves resource allocation, and minimises downtime.

Prescriptive analytics, the pinnacle of advanced analytics, provides actionable recommendations for perfecting processes. This phase answers the question: What should we do? Intelligent applications equipped with structured data sets can guide decision-making with unparalleled precision, ensuring processes stay stable and efficient.

However, advanced analytics is not without its challenges. For these solutions to deliver value, data must be clean, structured, and integrated into a unified architecture. Standards like OPC UA facilitate seamless data exchange, while robust data ontologies ensure consistency and cut redundancies. Manufacturers must also address cybersecurity concerns, balancing the need for secure data transmission with the opportunities presented by dynamic supply chain networks.

At JSP Advanced Solutions, we understand that advanced analytics is not about deploying the most sophisticated technology overnight. It is about building a scalable, secure, and intelligent infrastructure that supports continuous improvement. From predictive models that find quality inconsistencies to intelligent applications that prevent failures, our solutions empower manufacturers to take control of their operations and unlock new levels of precision and efficiency.

The era of advanced analytics is here. By taking deliberate, informed steps today, manufacturers can future-proof their operations and position themselves as leaders in the particle foam industry.

AI Agents: The Game-Changer

Copyrights: JSP

AI agents is the next evolutionary step in applying technology to traditional manufacturing. An AI agent for manufacturing is an intelligent system designed to autonomously or semi-autonomously perform specific tasks or make decisions to optimise various aspects of manufacturing processes. AI Agent takes the intelligence of AI and turns it into action like answering question, automate tasks or handling to-do lists.

The main characteristics of an AI Agent is their ability to understand the task, think about how to approach the task and how to act to complete the task. AI Agent could assist traditional manufacturing like particle foam, through a simple interface with a user (f.e. machine operator), while in the background being powered with a workflow and able to receive inputs like questions or commands, then understanding the questions and find the best way to respond, next to take action–provide answers, recommendations, or perform the task itself, and finally to learning, so the more you use it, the smarter it gets.

When integrated with structured data architecture, these systems can offer unique capabilities, for example:

Autonomous Agents: Predict machine failures, trigger maintenance, and ensure operational continuity.

Proactive Agents: Adjust parameters in real-time to meet CO2 reduction goals or minimise downtime.

Interactive Agents: Collaborate with operators to refine processes and improve outcomes.

Action-Oriented Agents: Streamline data aggregation, saving hours in reporting and decision-making.

These AI agents can transform how shop floors run, especially during night shifts or periods of limited supervision. For maximum effectiveness, however, domain experts must guide their training, ensuring outcomes stay credible and actionable.

Preparing for the Digital Future

Even medium-sized companies with outdated equipment can seize the opportunities of digital transformation. The key is a systematic approach:

Organise raw shop floor data into structured formats.

Adopt communication standards like OPC UA for interoperability.

Prioritise cybersecurity to balance data privacy with the demands of dynamic supply chains.

By aligning data architecture with business goals, manufacturers can create a robust foundation for AI-driven solutions and advanced analytics. Early adopters will secure long-term competitiveness and adaptability.

What This Means for You

JSP Advanced Solutions is uniquely positioned to lead this transformation. By combining decades of particle foam expertise with cutting-edge analytics and technological innovation, we offer unmatched value to manufacturers seeking to modernise their operations.

The particle foam industry has the resources, talent, and tools it needs to evolve. By acting now, we can deliver innovative, precise, high-quality applications that meet and exceed customer expectations. Let’s take the first steps together to redefine what’s possible in particle foam manufacturing.

Embrace Innovation: The particle foam industry must innovate to stay competitive, particularly in the automotive sector.

Focus on Sustainability: Aligning with climate goals and adopting sustainable materials and processes is crucial.

Leverage Technology: Integrating human expertise with advanced technology like AI and data analytics can drive the next phase of innovation.

Build Trust with Precision: Use real-time analytics and advanced sensors to ensure precision and build credibility.

Adopt Advanced Analytics: Rethink infrastructure and data management to leverage advanced analytics for operational efficiency.

Utilise AI Agents: Implement AI agents to optimise manufacturing processes and improve outcomes.

Prepare for Digital Transformation: Organise data, adopt communication standards, and prioritise cybersecurity to future-proof operations.

Written by Robert Płuska, Managing Director – JSP Advanced Solutions. With 18+ years of experience, Robert helps SMEs boost revenue and sustainability through solutions for industrial connectivity, data engineering, workflow automation, machine learning and AI advanced analytics for the particle foam industry.